Kyocera introduces its variety of innovations at EMO Hannover 2023

From September 18-23, the company participates at the trade fair in Hannover, Germany, following its approach for more sustainability by advancing productivity.

- Industrial Tools

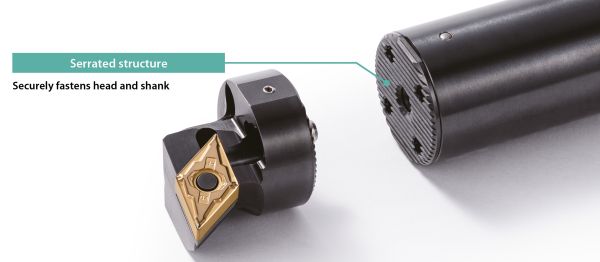

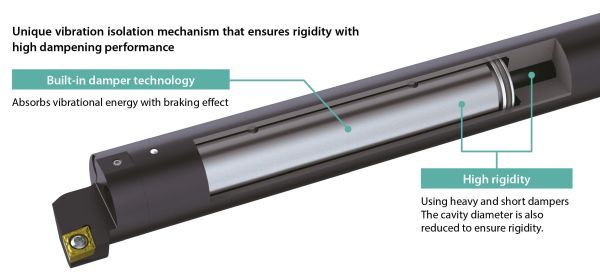

Kyoto/Neuss - Kyocera participates at EMO Hannover 2023 (Hall 5, stand D70), which takes place from 18 to 23 September. The company will be showcasing its all-new range of cutting-edge tools and solutions designed to support the metalworking industry, specifically automotive, electric vehicle, aerospace and energy sectors. Kyocera’s durable, high performance tools help manufacturers maximize efficiency in metalworking operations. By leveraging innovative materials and the latest technology, Kyocera’s offerings provide users with an optimized overall machining experience starting from new coatings for milling and turning to new milling cutters for a wide range of applications.

High-performing and durable products

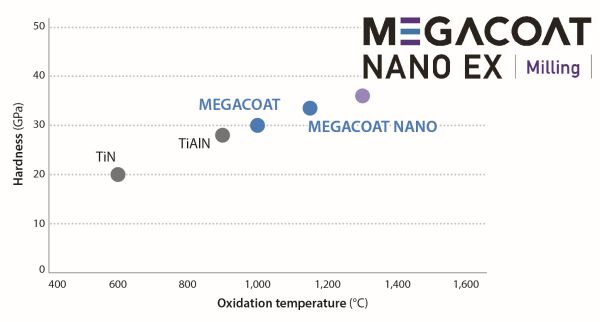

Kyocera’s products stand for excellent quality and durability. In doing so, the company introduces new grades series PR18 (PR1825, PR1835, PR1810) for next-generation PVD coating. These three new grades can be applied to current and new milling cutter systems, including face mills, shoulder face mills, profile cutters and high feed cutters. Due to Kyocera's innovative double coating technology with a special nano-coating called MEGACOAT NANO EX, customers can expect to get up to 2.5 times longer tool life than they would with conventional tools.

Product overview

| Product name | Characteristics | |

|---|---|---|

| PR1825 | - designed for steel - wear resistance oriented - excellent balance of hardness, toughness and versatility |

|

| PR1835 | - designed for steel and stainless steel - stability oriented - offers superior impact resistance and stability by utilizing a proprietary particle shape for improved thermal conductivity |

|

| PR1810 | - designed for cast iron - use of a proprietary base material with excellent thermal conductivity - achieves stable processing of cast iron |

With the introduction of PR115S and PR120S, Kyocera has developed special PVD-coated carbide grades for machining heat-resistant alloys. The new grades feature a unique carbide substrate with powerful heat-resistant properties. Additionally, MEGACOAT TOUGH, a new PVD coating technology, ensures longer tool life and stable machining. However, PR115S is the first recommendation for continuous finishing of heat-resistant alloys, while the PR120S is the first recommendation for continuous finishing to light interrupted machining of stainless steel.

About EMO 2023 Hannover

Taking place every two years, EMO (Exposition Mondiale de la Machine Outil) is one of the world’s most important trade fairs for the machining industry. As services and products continue to evolve, the show has become more focused on all aspects of manufacturing technology, as well as related topics and issues such as industry and cross-industry networking and education. In the 2023 edition, Kyocera will be located in the hall 5 at stand D70.